Electrification of construction equipment, the feasibility of using lignin as a partial replacement for bitumen and cool pavement were among ideas discussed at a Ontario Road Builders’ Association Summit session.

During the session titled New Ideas: Driving Forward to the Cool, Electric, Integrated and Greener Future, Alastair Hayfield of Interact Analysis Greater Northampton Area, U.K., a market intelligence company that focuses on new technologies, said electrification in the construction and off-highway markets will be important over the next five to 10 years.

“I don’t think it’s any particular surprise that there is a global push at the moment to reduce emissions and improve efficiency. A key takeaway is no industry is immune from this,” he said. “Every industry, be it construction, airlines or industrial production is going to have to step up to meet the challenges of reducing emissions and improving efficiency.”

As trucks and delivery vehicles electrify, companies are going to look to see how they can do the same for off-highway vehicles.

“These machines are coming. They are coming in large volume and it’s good to be prepared and ready for this technology,” Hayfield explained.

“It’s going to be difficult to see delivery trucks, buses, transportation vehicles being zero emission and then having a polluting heavy excavator or wheel loader operating next to them.”

He often hears electrification is too difficult in the construction or heavy industry.

“Although these machines cost more upfront, they tend to be a lot less to operate,” he said. “There are many more machines now available and there are numerous trial projects across Europe, even some in Canada, that are starting to address how these vehicles can be charged and how they can be brought into operations effectively.”

Natacha Mongeau, of Montreal-based FPInnovations, an organization that specializes in the creation of solutions to accelerate the growth of the Canadian forest sector, talked about a project started in 2020 which consists of using lignin to substitute a portion of the bitumen in asphalt, which has been the subject of many studies over the years.

“Various types of lignin show all kinds of advantages that could respond to the pavement industry’s challenges,” said Mongeau, adding studies have been done in other parts of the world. “The objective of our project was to make the demonstration of this product under our much colder, northern climate, under our Canadian regulations and with the lignin that our industry can produce. Our initial lab results showed that we should generally target five to 10 per cent lignin to meet performance in northern climates.”

Lignin is one of the most abundant polymers in nature, known as the natural glue of wood, she explained.

“During the craft pulping process lignin is removed from wood chips to liberate the fibres that are used for pulp paper and tissue production,” Mongeau said. “Lignin residues end up in an aqueous solution which is called the black liquor…To produce pure lignin, the black liquor is oxidized, acidified, coagulated and then filtered before the lignin is washed and dried.”

Before bringing new asphalt on the road, an in-depth lab testing program was conducted. The first on-road trials in Canada are in Alberta, Ontario, Quebec City and Thunder Bay.

“The main difference was that we could smell the trucks coming to the construction site. It has a smell of burnt wood,” she said.

“The price of lignin seems to be in the range of bitumen prices and we’re developing additional improvements to reduce the cost and carbon footprint even more.”

The biggest advantage is on roads that are prone to rutting, Mongeau said. From the primary data obtained during the trials a full lifecycle analysis is being conducted.

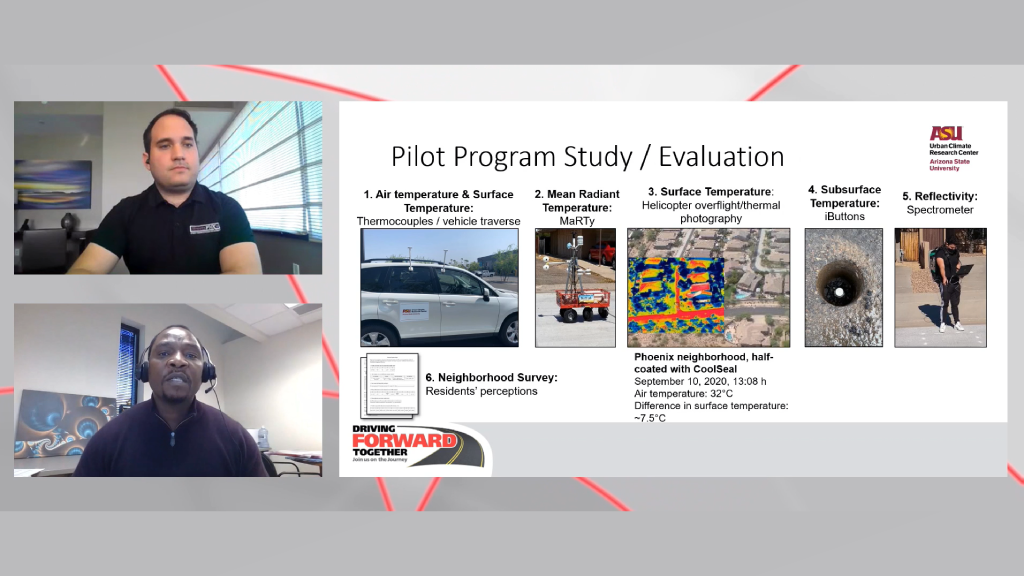

Ryan Stevens from the City of Phoenix, Arizona, talked about the city’s cool pavement pilot program. Phoenix is one of the largest hot cities in the United States. Cool pavement is one of the tools used to respond to urban heat.

“We expect some heat mitigation benefits and that helps our residents for health, for energy savings and also we expect it to help maintain our pavement,” said Stevens. “That’s a very important topic as a municipality that we are adequately maintaining our roads. This is a product and a process that we feel does both, gives us a maintenance benefit and a health and comfort benefit.”

The pilot project was implemented in nine locations across the city. In the first phase, over six million square feet of cool pavement coatings have been placed in the city.

“One of the ways we innovated was taking it from a slow squeegee process to a very quick spray process,” said Stevens. “Over 99 per cent of our streets in Phoenix are asphalt so it’s important for us that it’s compatible and we can maintain it.”

Recent Comments

comments for this post are closed