A robotics pioneer says the future of machines in construction is quality rather than an illusion of productivity.

Dusty Robotics co-founder and CEO Dr. Tessa Lau spoke at the Independent Contractors and Businesses AssociationŌĆÖs 2024 ┬ķČ╣┤½├ĮĖ▀ŪÕion Innovation Summit in Vancouver on Oct. 3 during a session titled, The State of Robotics in ┬ķČ╣┤½├ĮĖ▀ŪÕion – TodayŌĆÖs Reality and TomorrowŌĆÖs Possibilities.

Lau said contractors are being asked to do more with tighter budgets and faster timelines but the problem isnŌĆÖt productivity, itŌĆÖs a question of quality.

ŌĆ£People come to us looking for a robotic solution to increase productivity, and I think theyŌĆÖre thinking of the wrong thing,ŌĆØ Lau said. ŌĆ£They should be focused on quality because in order to deliver the number of buildings we need to deliver as an industry over the coming decades, we (have to) stop making so many mistakes because thereŌĆÖs so much waste.

ŌĆ£┬ķČ╣┤½├ĮĖ▀ŪÕion is the only industry I know where itŌĆÖs totally normal to do rework because you got it wrong the first time,ŌĆØ she added. ŌĆ£If you have more productivity, all it means is you build the wrong thing faster.ŌĆØ

Where robots can help is to increase the quality of a project form the outset by enhancing both collaboration and communication using virtual design and construction (VDC).

ŌĆ£VDC tends to be invisible and overlooked and in many cases is viewed as a cost centre, a thing you have to do in order to win the bid and not as a way to drive quality,ŌĆØ Lau said.

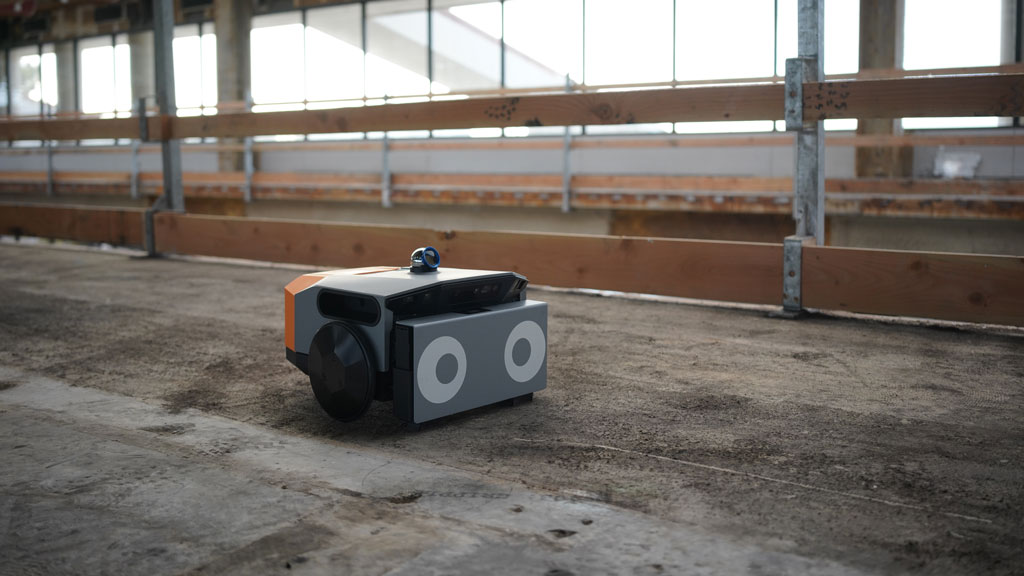

Robots are digital natives, she explained, and can use VDCŌĆÖs information to improve conditions in the field, citing Dusty Robotics own FieldPrinter product which prints plans directly onto a project floor as an example.

ŌĆ£In our case we use the VDC information to print and communicate that information out to the field. In the case of other robotic systems, they use the information to know what to build where and so VDCŌĆÖs output is essentially the instruction manual for the robots of the future,ŌĆØ Lau said.

Though it seems obvious, she added, the ability to print not just lines but words on a surface makes a big difference for communication.

ŌĆ£We found our customers at Dusty have printed more than 1.6 million words over the past four years. ThatŌĆÖs more than 23 full-length novels that our customers have written. What theyŌĆÖre doing with those words is giving instructions to field crews,ŌĆØ she said.

ŌĆ£VDC is basically the planning component that allows you to see whatŌĆÖll happen next and look around corners. Dusty and automated layout gives VDC teams a way to communicate all of that knowledge that theyŌĆÖve built up out to the field where they can actually use it.ŌĆØ

Having data on the ground and in front of people also encourages safety and discourages conflict, she said.

ŌĆ£We found on a typical jobsite the average contractor has 17 interactions with people from other companies and half of those interactions involve conflict,ŌĆØ she said. ŌĆ£That conflict happens because they donŌĆÖt have the information they need or are working on different versions of information and come to loggerheads with a different view of reality. With a single view of reality printed under your feet, it leads to much less sources of conflict and a safer jobsite.ŌĆØ

Lau also assured those currently in the industry that robots are not likely to replace their jobs in the future.

ŌĆ£At least in our case, our robots are being used more as power tools than to replace labour. If youŌĆÖre a foreman doing layout youŌĆÖre one of the most valuable people on the jobsite and donŌĆÖt want to spend┬Ā weeks on your hands and knees marking plans on the floor,ŌĆØ she said.

Instead, the foreman can operate the robot themselves or train an apprentice with confidence the device will transfer information accurately from the digital model to the floor.

ŌĆ£What that means is the foreman spends more of their time managing projects, training workers, dealing with materials deliveries and doing things they can contribute to the project,ŌĆØ Lau said.

Recent Comments

comments for this post are closed