In the new year, Cheeseman’s Concrete Removal Ltd. will use remote-controlled demolition robots to take down Vancouver’s former 29-storey Four Seasons Hotel tower to the fourth floor making way for a new tower and hotel renovation.

But for owner Balfour Cheeseman, the over-riding aspect of the work is that he is using technology that is safe for neighbours, workers onsite and the general public. It is technology that is 20-years behind where it should be in the construction industry, he said, as concerns grow regarding worker occupational health and safety.

“It is still a niche market,” he said, adding many in the construction industry are not aware of robotic demolition and its’ benefits over conventional demolition techniques.

Cheeseman runs a fleet of electric Brokk robotic demolition equipment that can be equipped with heads: an 80-tooth grinder, jaws that can crunch concrete and sheer metal, and a heavy-duty jackhammer (equipped with a spray nozzle to mitigate silica dust). The unit operates remotely and can access tight or confined spaces, work on platforms and be craned onto a building’s story.

“A lot of it is word of mouth,” he said of business that lands on his doorstep. “When someone is stuck on something and looking for a way, they start asking around.”

Those one-off situations have turned into repeat clients, boosting his list to many major companies.

“For 25 years, I put down concrete and for the past 25 years I have been taking it up,” he said.

When he first got into concrete removal, his competition was the guy with a truck, a jackhammer and a compressor. It was not the scenario that Cheeseman wanted to chase – for good reasons.

Hand and arm vibration syndrome is the major concern for those repeatedly performing jackhammer work as vibrations impact joints and the nervous system. Cheeseman opted for robotics. It was a more expensive but protected the worker both onsite and in the long-term.

Then he went a step further. Concerned about diesel fumes from equipment and the impact on workers, he opted for all his units to be electric, either running off a supplied power feed or a generator.

“The generator runs on diesel,” he said, but when it is used, it is sited well away from the work area so that onsite workers are not impacted.

Short-term diesel exposure ranges from irritation to the eyes, throat and lungs. The International Agency for Research on Cancer classifies long-term exposure to diesel engine exhaust as carcinogenic to humans, determining that exposure to diesel exhaust emissions increases the risk for lung cancer and possibly bladder cancer.

Cheeseman sees another reason for using robotics. It is the growing concern of silica dust and other airborne particulate when a building is imploded.

“They imploded the Tropicana in Las Vegas (Oct. 9),” he said, as he watched it on TV.

It was a flawless implosion but the plume of dust that emerged was startling.

“It happened at 2:30 a.m. and you couldn’t see the city,” he said, as the legendary 67-year-old hotel’s two 23-storey towers came down.

Health authorities issued a “Trop-dust” air quality advisory.

When the hotel tower of the former Four Season is removed to make way for a new structure, the Brokk robot’s jaws will pull down sections of exterior concrete walls while a jackhammer removes concrete floors. The robot’s jaws have tremendous crushing strength.

“It can squeeze the wall so hard it will just crumble,” he said.

Machines will scoop the debris into bins to lower to the ground.

Cheeseman’s fleet of eight Brokks consists of the 60, 70, 100, 110, 180, 200, 260 and 500 units which provide him with both power and site versatility. The smaller machines are only two feet wide and units up to the 180 will fit through a normal door.

The robots can also do precision work where the depth of the concrete removed has to be accurate, according to Cheeseman. His company worked a Kemano dam retrofit where a layer of concrete on a penstock had to be removed in order to place a valve.

At the Kitsilano pool, a robot jackhammered concrete to find a leaky pipe. Refractory work in pulp mill and concrete plants are common tasks. And, perhaps the most challenging job, the Golden Ears Bridge where concrete piling had to be precisely aligned to join platforms.

Cheeseman said the Brokk robots are also known for their reach as they have a three-part arm system. The Brokk 500 unit’s three-part arm system can reach up 24.3 feet vertically and 23 feet horizontally.

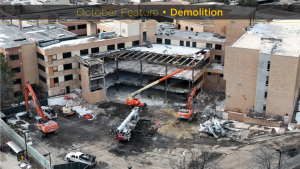

The Brokk units’ ability to reach came into play recently in the demolition of a three-storey residential building in the 100 E. Hastings area which was precariously close to other buildings in this older section of Vancouver.

The Brokk units were able to reach up and pull everything to the centre.

“It took the danger away from it falling on other buildings,” Cheeseman said.

Recent Comments